Coolant Management

Assembly & Production Lines

The challenges in Assembly & Production line automation is achieving the cycle time keeping in view the flow of various components of the product and the manipulation required to assemble the components. The lines are a combination of Floor & Overhead Conveyors, Tilters, Turntables integrated together to assemble various components together. With our expertise, we can support you right from creating the floor plan to deciding the process which will ease the assembly process.

TRAMP OIL REMOVAL SYSTEMS

Technical specification:

- Single phase 240 VAC Power consumption : 0.4 kWh

- Flow rate : 15 LPM outlet

- Pipe dimensions : Diameter 32 mm

Application Areas:

- Coolant in machine tools (CNC, VMCS)

- Degreasing tanks, Washing machines, ETP Tanks.

Application Areas:

- KTEC – Portable Systems for Machine Tools.

- KTEC-D – For Degreasing tanks/Washing Machines.

- KTEC-ETP – For Effluent Treatment Plants (ETP), Vehicle Washing Center

Advantages

- Plug and play system

- Removes oil droplet upto 20 micron size

- No consumable parts

- Increases fluid life by 100%

- Low operating consts

Tramp Oil are sources of following problems:

- Corrosion and stain, Detergency and residues

- Dermatitis, Foam, Smoke, Mist

- Excessive tool wear due to reduced lubrications properties

Tramp Oil on coolant Clean coolant with KTEC

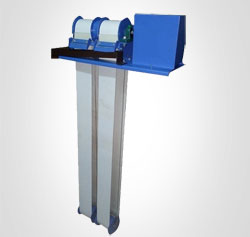

KTEC Belt Skimmer

Single Belt, Double Belt SMedium Duty Gear Box (25 W), Heavy Duty Gearbox (0.25 hp) SWidth: 50 mm, 75 mm, 100 mm SLengths: 300 - 2000mm SBelt Material: SS, PVC SWipers: PU

We have wide range of belt skimmers for various applications.

Machine Centers, Washing Machines, Degreasing, ETP

KTEC SUMP SUCKER

Cleans dirty machine sump in minutes

Cleaning machine sump can be time, labor consuming activity with all the mess going on around creates untidy shop floor. Now introducing fast and reliable way to clean machine sump KTEC Air operated Sump Sucker. KTEC Sump Sucker sucks all the fluid (Coolant or Near oil) along with the swarf from the machine sump just like a vacuum cleaner with more power.

Once the machine sump is filtered, fluid can be returned to the sump again that too within seconds and guess what swarf is entrapped in the system and can be removed easily. KTEC Sump Sucker uses compressed air to create a powerful suction to entrap all chips and fluid. Same compressed air is used to return fluid back to sump.

Advantages :

- Fast and Reliable

- Easy to clean.

- Equipped with 50 micron

- filter bag.

- Low maintenance.

Technical specifications:

- 200 Liter Sump Size.

- 25 kg Swarf (Chips) Basket.

- 50 micron filter bag.

- Flow rate upto 100 LPM

System Requirements :

- Moisture Free Compressed Air at 5 bars.

Models :

- 100L, 200L, 400L Tank capacity

KTEC Magnetic Separator

KTEC Magnetic Separators are made with powerful rare earth magnet drums which produces magnetic field 75mm above the drum. Very fine particles will be arrested without slip. The magnetic material will not loose its strength even after number of years of use. These filters are available in 30 LPM to 1200 LPM filtering capacity. These filters can be coupled with paper band. cartridge filters etc. We also manufacture range of paper bands filtration machines.

MAGNA CLEAN

Magnetic Filtration can be used to remove 100% ferrous and Para-magnetic particles such as steel, cast iron, carbide etc. down to sub-micron levels from all industrial fluids where contamination of a liquid is a major problem. The removal of these particles results in longer fluid life and improves the surface finish of your products, increases component accuracy and reduces wear on your machinery and tool.

Magnaclean models

Single Candle, Triple Candle, Offline

Magnetic Filtration

Unlike conventional filters, Magnaclean is not particle size sensitive, if the particle is ferrous, no matter how small (even sub micron) Magnaclean will remove it! This process will not strip the oil of additives but will help to subdue bacterial growth.

Applications where to use magnetic filtration

Grinding, Honing, Lapping & Milling operations on conventional & CNC machinery, Fine finishing operations, Gun drilling, Shaving operation, Wire & EDM processes, Laser cutting operations, Injection molding cooling & heating systems, industrial part washing, Press break lubricants, Post drill head operations, Saw sharpening, Pump protection pre-filtration, Quenching operations

Magnetic filtration provides these advantages over traditional barrier filtration

No consumables used, Sub-micron filtration improved surface finish, Better product accuracy Longer lasting fluids, Minimal fluid loss No disposal cost, Minimal fluid loss No disposal cost, Minimum running cost Rapid return on investment, No back pressure